Der Umgang mit hohen Temperaturen ist unsere Kernaufgabe.

Wir nennen das:

Smart. Temperature Solutions

Die Zukunft benötigt smarte Lösungen

Die Lösungen, die wir schaffen, schützen Mensch, Maschine und Umwelt. Für uns ist dies die Motivation und der Ansporn. Wir arbeiten täglich daran, mit kreativen und durchdachten Hochtemperatur Dämmsystemen einen wichtigen Beitrag zur energetischen Optimierung zu leisten. Der Wirtschaftlichkeit und Umwelt zuliebe.

Sicherheit

- Reduzierung der Oberflächentemperatur

- Steigerung der Arbeitssicherheit

Effizienz

- Steigerung des Wirkungsgrads

- Vermeidung von Temperaturverlust

Umwelt

- Reduzierung von Emissionen

- Steigerung der Haltbarkeit

Ihre Anforderung, unsere Lösung

Geringere Temperaturen, mehr Sicherheit

Die Erfüllung der Emissionsverordnung, Brandschutz oder SOLAS gehören zu den Kernthemen unserer Kunden und sind von größter Bedeutung. Mit Lösungen zur Reduktion von Oberflächentemperaturen auf bis zu 60 °C und den maximalen Temperaturerhalt im System, erfüllt die tmax die maximale Betriebssicherheit und Ausfallsicherheit Ihrer Maschinen.

Brandschutz

Erfüllung Abgasnorm

Wirkungsgrad

steigern

SOLAS

Schallschutz

Berührschutz

Lebensdauer

steigern

RETROFIT

tmax als Problemlöser im Hochtemperaturbereich ausgezeichnet

Die tmax zählt bereits zum 4. Mal zu den Top-Innovatoren und hat 2024 erneut die Auszeichnung als innovativster Problemlöser im Hochtemperaturbereich erhalten. Damit untermauert die tmax seine Kompetenzen und Marktführerschaft als professioneller Lösungsanbieter.

Hochtemperaturdämmungen: keine Hitze, kein Feuer

Drei fantastische Hochtemperaturlösungen

In der Kombination unschlagbar

Ein breites Produktspektrum an unterschiedlichen Isolier- und Dämmmaterialien ermöglicht jede Höchsttemperatur Herausforderung zu lösen.

Metallische Isolierung

- Hoher Dämmwert

- Hohe Langlebigkeit

- Leichte Montage

- Wartungsfreundlichkeit

Folien Isolierung

- Passgenau, für komplexe Formen

- Geringes Gewicht und platzsparend

- Optional: Wasserabweisender Dämmstoff

- Optional: Verstärkter Schallschutz

Textile Isolierung

- Perfekter Berührschutz

- Schnelle Montage und Demontage

- Kurze Entwicklungszeiten

- Geringe Werkzeugkosten

Kombinierte Isolierung

Nicht immer ist nur ein Isoliertyp geeignet. Immer häufiger sind unsere Lösungen so individuell wie Ihre Herausforderung. Wir kombinieren die Vorteile geeigneter Isoliertypen und entwickeln eine speziell auf Ihre Anforderung zugeschnittene Isolierlösung.

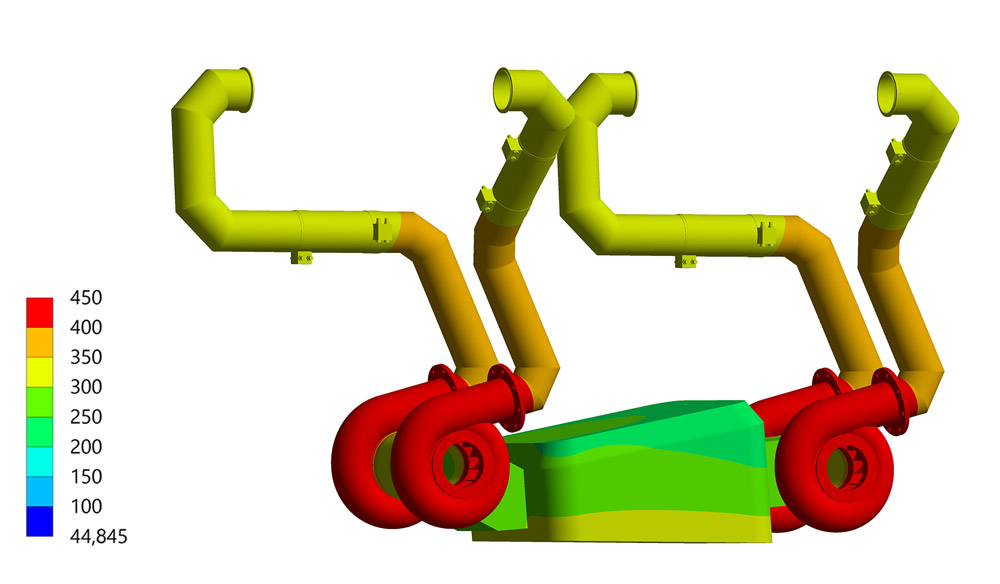

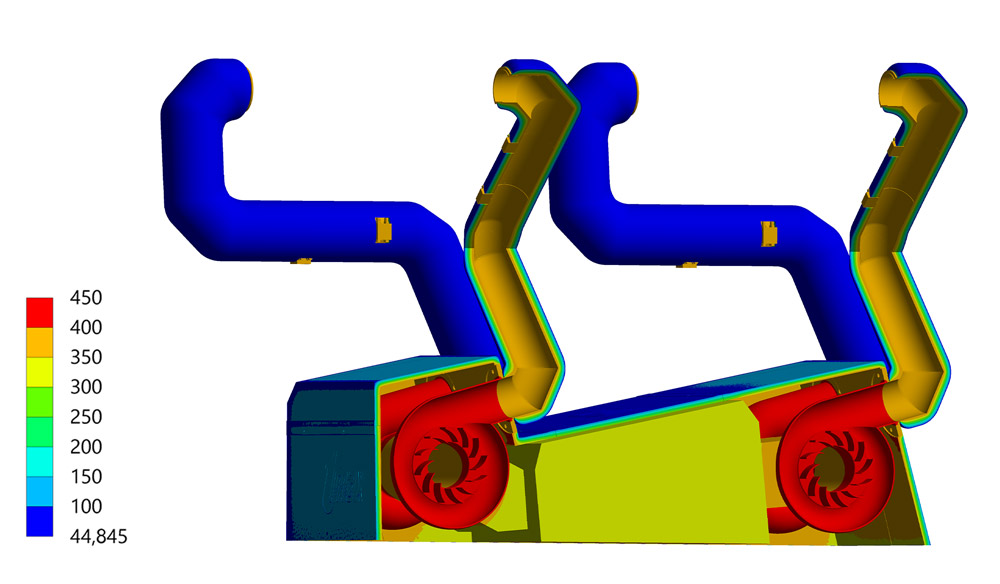

Durch Simulationen: weniger Prototypenzyklen und Kosten sparen

Die Entwicklung neuer Produkte kostet Zeit.

Einzigartig in der Branche: Mit den tmax Simulationen sparen Sie Schleifen im Entwicklungsprozess.

Drehen Sie sich bei Konzeption, Konstruktion und Testphasen nicht länger im Kreis.

- Thermische Schwachstellen finden

- Schwingungssimulation zur Vorhersagung des Verhaltens eines virtuellen Bauteils

- Simulation zur Beurteilung von Konzepten und Konstruktionen

So gelingt es uns noch vor der Fertigung eines Prototyps, dessen ideale Auslegung zu finden.

Die Zukunft hat ein Hitzeproblem, tmax die Lösung

Viele Länder haben das Ziel ZERO CO₂-Emissionen. Die Zukunft ist ein Motorenmix mit der Verwendung unterschiedlicher Kraftstoffe. Wasserstoffantriebe spielen hierbei eine große Rolle. In naher Zukunft werden schon serienreife Motoren den Einzug in die breite Masse finden.

Und tmax ist dabei, mit nachweislich ausgezeichneten Ergebnissen in der Effizienzsteigerung.

Als Branchenführer für intelligente Isolier- und Dämmlösungen für den Wasserstoffmarkt, steigern wir den Wirkungsgrad von Wasserstoffmotoren, Turboladern und Krümmern.

Geringere Temperaturen,

mehr Sicherheit

Von dieser Leistung träumen andere Isolierungen

Die Erfüllung der EU-Emissionsverordnung und Brandschutz sind unter anderem im Off-Highway Bereich von größter Bedeutung. Wir bieten Lösungen für eine Reduzierung der Oberflächentemperatur auf bis zu 60 °C an, wie kein anderer und damit die maximale Betriebssicherheit und Ausfallsicherheit für Ihre Maschinen.

Weltweit Ihr Partner vor Ort. Immer direkt.

Seit der Gründung 1976 hat die tmax Germany GmbH den Umgang mit hohen Temperaturen zur Kernaufgabe gemacht. Tmax ist mit sieben Unternehmen in sechs Ländern vertreten. Mit der Gründung des Standortes in den USA im Jahre 2014, wurde ein neuer Markt erschlossen, der große Wachstumspotenziale bringt. Im Jahr 2021 wurden aufgrund der hohen Nachfrage nach Isolierlösungen ein Produktionsbetrieb in Rumänien gegründet.

Entfalten Sie Ihr

Potenzial mit tmax!

Eine Karriere bei tmax bedeutet, dass Sie wirklich etwas bewegen können. Als agil lebendes und denkendes mittelständisches Unternehmen, fördern wir offene Diskussionen und kreative Ideen.